| Comparison Item |

Ash Removing System of Waste Lubricant

( by EICOH ECOSPA Corp.) |

Waste Lubricant Clarification System

( by Other Companies ) |

| Purpose |

・Recycling and effective use of waste oil

・Use expansion of treated oil |

・Recycling and effective use of waste oil |

| Material waste oil |

・Mainly waste engine oil

・Waste lubricant

・Clarified waste lubricant (for quality improvement and use expansion) |

・Mainly waste engine oil

・Waste lubricant |

| Treating method |

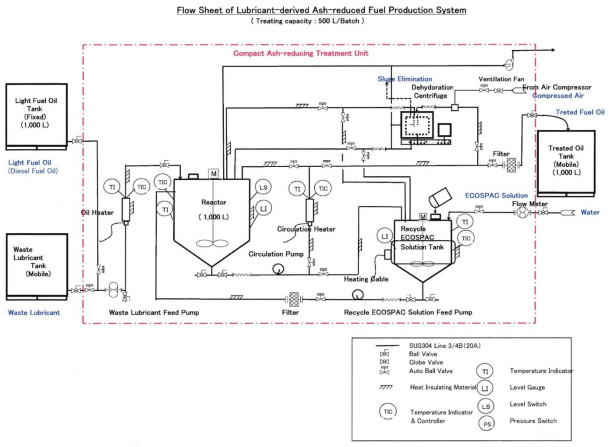

・Chemical treatment using special reagent (ECOSPAC) |

・Physical cleaning using filter and / or centrifuge |

| Treating facilities |

・Compact assembled unit

・According to demand, large plant installation is possible. |

・Large plant |

| Product (Treated oil) quality |

・Ash content: 0.05% or less

・It meets to JIS specification:heavy oil type 1 No.1 (A heavy oil) |

・Ash content: 0.5 to 1.0%

(Product specification: 1.0% Max.) |

| Product (Treated oil) use |

・Available for general boiler and diesel engine |

・Not available for general boiler and diesel engine

・For special use (incinerator, cement burning furnace, etc) that can be used even with high ash content. |

| Utilization in island countries, developing countries, etc. |

・Every countries have use of the product (treated oil) |

・It can not be used in countries where there is no special use of the product

(treated oil) |

| Product (Treated oil) Pricing |

・Pricing is easy because the product can be used for general use. |

・As the product is a special use, there is a possibility that the customer will request lower prices. |

| Economic efficiency of investment |

・It can be installed as a payout project

・The larger the plant, the more economical |

・Payout is possible depending on the price of the product (treated oil) |

| Maintainability |

・It is easy to maintain because the compact unit does not use special instrument and equipment |

・Specialists are required for maintenance and repair of the centrifuge |